Repairing Business Refrigeration Fixing: Techniques for Quick and Effective Fixes

In the realm of commercial refrigeration, the need for swift and specific troubleshooting methods is vital. When a refrigeration unit breakdowns, the consequences can be disruptive and costly to company procedures. Comprehending the common concerns that afflict commercial refrigeration systems and having a toolkit of analysis techniques available can make all the difference in quickly identifying and correcting problems. As we browse via the ins and outs of troubleshooting business refrigeration repair, we will certainly uncover the vital techniques for fixing concerns efficiently, making certain that companies can maintain optimal air conditioning performance and reduce downtime.

Typical Commercial Refrigeration Concerns

Industrial refrigeration systems typically encounter a variety of functional issues that can disrupt their effectiveness and performance. One common problem is inappropriate temperature control, which can lead to food putridity and waste if not immediately dealt with.

In addition, refrigerant leaks posture a significant worry as they not just impact the cooling ability of the system yet also add to ecological harm. Regular cleaning and upkeep can help avoid this issue and lengthen the lifespan of the refrigeration system.

Diagnostic Devices and Strategies

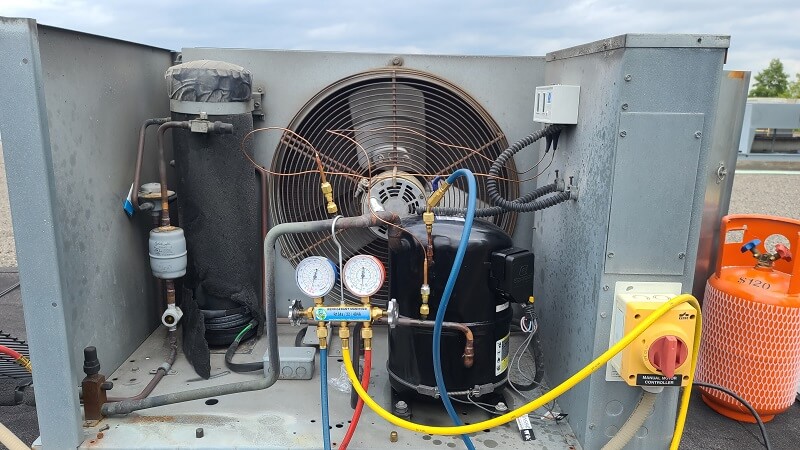

Efficient troubleshooting of industrial refrigeration systems counts heavily on making use of specialized analysis devices and techniques to identify and solve underlying issues efficiently. One necessary analysis device is the multimeter, which helps specialists determine voltage, existing, and resistance in numerous components such as compressors, motors, and thaw heaters. Thermostats are also critical for analyzing temperature level differentials across the system to pinpoint possible problems like cooling agent leakages or improper air flow. Furthermore, leak discovery devices like digital leak detectors or ultraviolet color kits are crucial for locating refrigerant leaks that can lead to system inefficiencies.

If the system has the correct cooling agent fee and identify any kind of leakages,Techniques such as stress screening using manifold determines can figure out. Visual inspections of parts for indications of deterioration, ice, or wear buildup are additionally essential in detecting problems. Data loggers can be utilized to check system performance over time and find trends that may show recurring issues. By incorporating these diagnostic tools and strategies, specialists can properly troubleshoot industrial refrigeration systems and give exact and fast repairs, decreasing downtime and ensuring optimum system efficiency.

Quick Solutions for Refrigeration Troubles

When faced with refrigeration troubles, service technicians can implement fast fixes to attend to common problems swiftly and successfully. One common fast solution is checking for a dirty condenser coil, which can cause the system to run inefficiently. Cleaning up the condenser coil routinely can improve the system's efficiency and avoid overheating. Another quick fix is making sure that the fridge is not strained, as overcrowding can restrict air movement and result in temperature level variances. Readjusting the shelving to permit appropriate air flow can frequently solve this issue. In addition, checking the door seals for go to these guys any type of signs of wear or damage and replacing them if essential can aid maintain the integrity of the seal and protect against air leaks. If the refrigeration system is not cooling down appropriately, inspecting and readjusting the thermostat setups may provide a quick remedy prior to even more in-depth troubleshooting is called for. By applying these quick repairs, technicians can address typical refrigeration troubles successfully and keep business refrigeration systems running smoothly.

Preventative Maintenance Tips

Applying a positive maintenance routine is vital for guaranteeing the durability and optimal efficiency of business refrigeration systems. Normal upkeep not only helps protect against expensive break downs yet additionally ensures that the equipment runs efficiently, saving power and reducing total operating expense. Here are some preventative maintenance ideas to keep industrial refrigeration systems running smoothly:

Inspect and Change Filters: Dirty filters can restrict air movement, making the system work harder and potentially causing damages. Inspect and change filters on a regular basis to stop problems.

Inspect Seals and Gaskets: Leaky seals and gaskets can bring about my blog temperature changes and energy wastefulness. Replacing and checking damaged seals can aid maintain constant temperatures.

Professional Assistance and Solutions

To keep the ideal efficiency accomplished through routine preventative upkeep, seeking expert assistance and services for commercial refrigeration systems is essential. Expert professionals have the proficiency and specialized understanding called for to diagnose and address complex issues successfully. When facing challenging refrigeration troubles, relying upon expert support can conserve both money and time in the future.

Professional services supply advantages such as accessibility to advanced tools and equipment, making sure that repair work are performed successfully. Furthermore, service technicians are educated to comply with industry click here now regulations and security criteria, reducing the threat of crashes and guaranteeing compliance with lawful needs.

Conclusion

Finally, repairing business refrigeration repair needs an organized approach to determining usual concerns, using analysis devices and methods, executing fast solutions, and focusing on preventative maintenance. Specialist assistance and solutions may be needed for more complex issues - commercial refrigeration repair. By following these approaches, organizations can ensure their refrigeration systems operate successfully and properly, reducing downtime and possible losses

Comprehending the typical problems that afflict commercial refrigeration systems and having a toolkit of analysis techniques at your disposal can make all the distinction in swiftly recognizing and correcting issues.Efficient troubleshooting of business refrigeration systems relies greatly on making use of specialized analysis tools and methods to recognize and settle underlying issues efficiently. By integrating these analysis devices and strategies, service technicians can properly repair business refrigeration systems and give quick and exact repair services, reducing downtime and making certain optimal system efficiency.

By executing these quick fixes, specialists can deal with usual refrigeration troubles successfully and maintain industrial refrigeration systems running smoothly.

In addition, specialist assistance can help extend the life-span of business refrigeration systems by determining potential concerns before they escalate.